Reliable Spray Sealing Solutions for Brisbane

At Armstrongs Bitumen Asphalt, we offer professional spray sealing services designed to protect and enhance the lifespan of your surfaces. Whether you need a cost-effective solution for rural roads, driveways, or large commercial areas, our spray sealing services deliver durable and weather-resistant results.

Multiple-layer application

Sprayed seals can involve multiple layers of binder and/or aggregate, tailored to suit specific needs. Below are some of the most common types of multi-layer sprayed seals, though innovative practitioners may develop other combinations to address unique challenges.

These multi-layer seals deliver a durable, heavy-duty surface ideal for demanding conditions. Applications include haul roads, roads requiring snow clearing, and creek ford crossings.

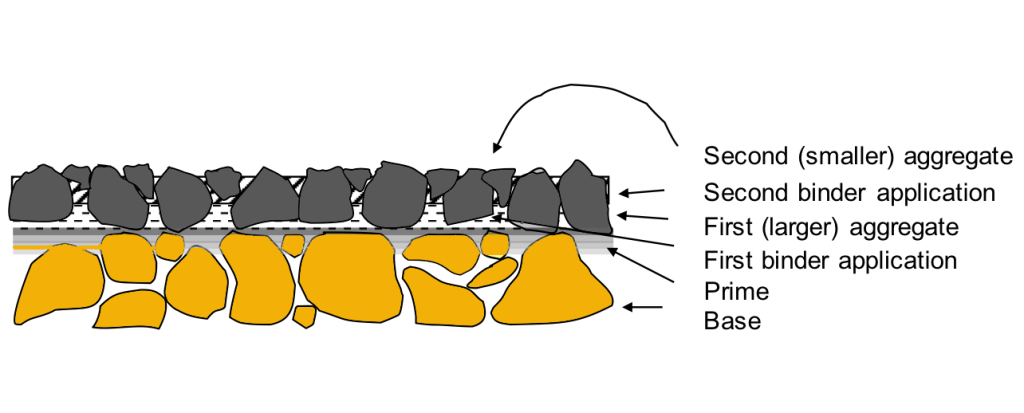

Double/double seal

A double/double seal is a two-layer sprayed seal technique that involves sequential applications of binder and aggregate. First, a layer of binder is sprayed and covered with large-sized aggregate, which is then rolled and swept to settle in place. Next, a lighter layer of binder is sprayed over the initial aggregate, followed by the application of smaller-sized aggregate. The smaller aggregate interlocks with the larger aggregate, filling gaps and creating a stable, durable surface.

Double/double seals are typically described by the sizes of the aggregate used. For example, a “14/7 double/double” refers to a 14 mm bottom layer of aggregate topped with a 7 mm layer. This method is widely used for its strength and longevity in demanding conditions.

Single/double seal

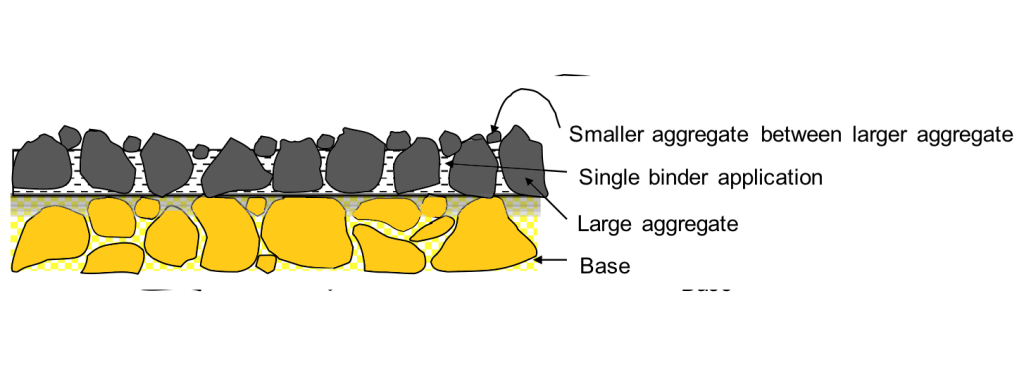

Scatter coat

A scatter coat is applied similarly to a single/double seal, with a key distinction: in a scatter coat application, the first layer of aggregate is spread at the normal rate used for a single/single seal. The second layer of aggregate, referred to as the scatter coat, is applied to provide temporary mechanical interlock between the larger aggregate particles.

This additional layer helps stabilize the coarse aggregate, preventing displacement or overturning caused by traffic during the initial curing and compaction phase of the seal. This ensures the integrity of the surface as it sets and strengthens over time.

Scatter coat

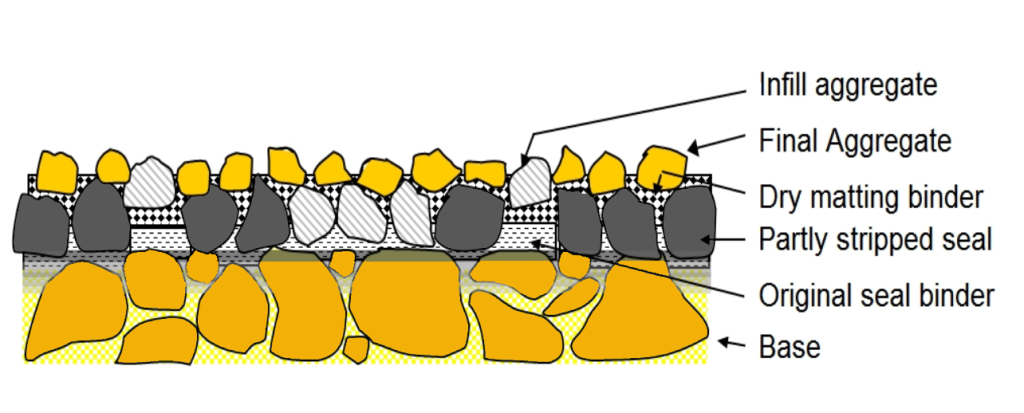

Dry matting

Dry matting, is a surfacing technique that involves two layers of aggregate with a single application of binder placed in between.

This method is particularly effective as a corrective treatment for stripped or partially stripped seals, as well as flushed bituminous surfaces. The process begins with spreading a single layer of aggregate over the existing surface or filling stripped areas. A layer of binder is then applied, followed by a second layer of smaller-sized aggregate to lock the first aggregate layer securely in place.

Dry matting provides a durable solution for restoring surface texture, improving skid resistance, and extending the life of compromised seals.

Dy matting

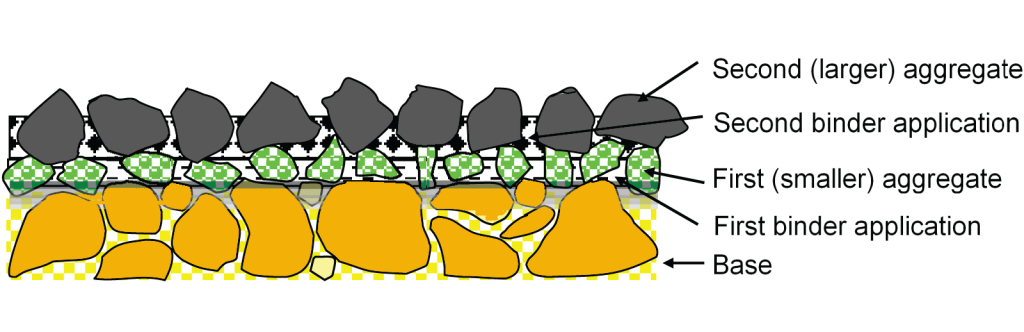

Inverted Seal

An inverted seal is a variation of the standard double/double seal, where the typical layering order is reversed. In an inverted seal, the smaller-sized aggregate is applied to the bottom coat, while the larger-sized aggregate is placed on the top coat. For example, instead of a 14/7 seal, it would be a 7/14 seal. Both applications are typically completed on the same day.

Inverted seals are particularly useful for treating surfaces with significant variation in transverse surface texture. They can also help reduce the risk of larger aggregate particles embedding into soft or unstable pavement materials, providing a more stable and durable surface.

Inverted seal

QUALITY MATERIALS

We believe that the key to a superior asphalt pathway lies in using high-quality materials and employing skilled workmanship. We source our materials from trusted suppliers, ensuring their durability, strength, and resistance to heavy foot traffic and environmental factors

Attention to Safety and Accessibility

Safety is paramount when it comes to commercial pathways. We design and construct pathways that meet the highest safety standards and comply with all relevant regulations. In our projects we pay attention to factors such as slope, drainage, and slip resistance to ensure a safe walking surface for employees, customers, and visitors

customised solutions

We recognize that each commercial property has unique requirements and design preferences. Our team takes the time to understand your specific goals and collaborates closely with you to create customized asphalt pathway solutions. Whether you require a straightforward and functional pathway or a more intricate design to complement your architectural style, we offer personalized recommendations and tailor our services to meet your specific needs.

CONTACT US

Complete this contact form and a member of the Armstrong Bitumen Asphalt team will be in touch!